Metabo Cam-type Portable Hand Pipe Beveling Cutting Machine

Product model:SCB

Processing caliber:φ14-φ114mm 1/2”-34”

Groove wall thickness:≤12mm

The knife dish speed:30-120r/min

Product material: chrome molybdenum steel, low temperature steel, titanium alloy steel, etc.

Product standards:GB/T 156;GB 1002;GB 2099.1;GB/T 5013.4;GB/T 5023.5;GB 5226.1;GB/T 11918;GB/T 13277.1;GB 16710

Generalization:

Cam-type self-centering cutting and beveling machine used for pipe high speed cutting and beveling suit to small size pipes.This series machine adopts METABO motor, main applied in the field of power plant pipeline installation, chemical

industry,shipbuilding, especially pipeline prefabrication and low clearance on site working, such as maintain thermal power

auxiliary equipment, boiler pipe valve.

High strength precision ring structure, suitable for all kinds of pipe cutting and groove processing, especially for large quantities of thin wall pipe cutting, groove processing.Using imported top quality as electric motor, low noise, long life, light weight, reliable performance, a wide range of speed regulation, with CE certification.Its speed control mode has two kinds: gear speed and electronic infinitely adjustable-speed, rated voltage 200 v, 50 hz frequency.

Features:

1、Automatic positioning center pipe, concentricity and vertical degree without manual adjustment;

2、Compact structure and beautiful, high strength aluminum fuselage, cabinet and delicate;

3、Using new synchronization into the organization, uniform feeding, cutting tool of longer life;

4、Easy installation fast, simple operation, convenient maintenance;

5、Cutting groove and a one-time, processing efficiency is very high;

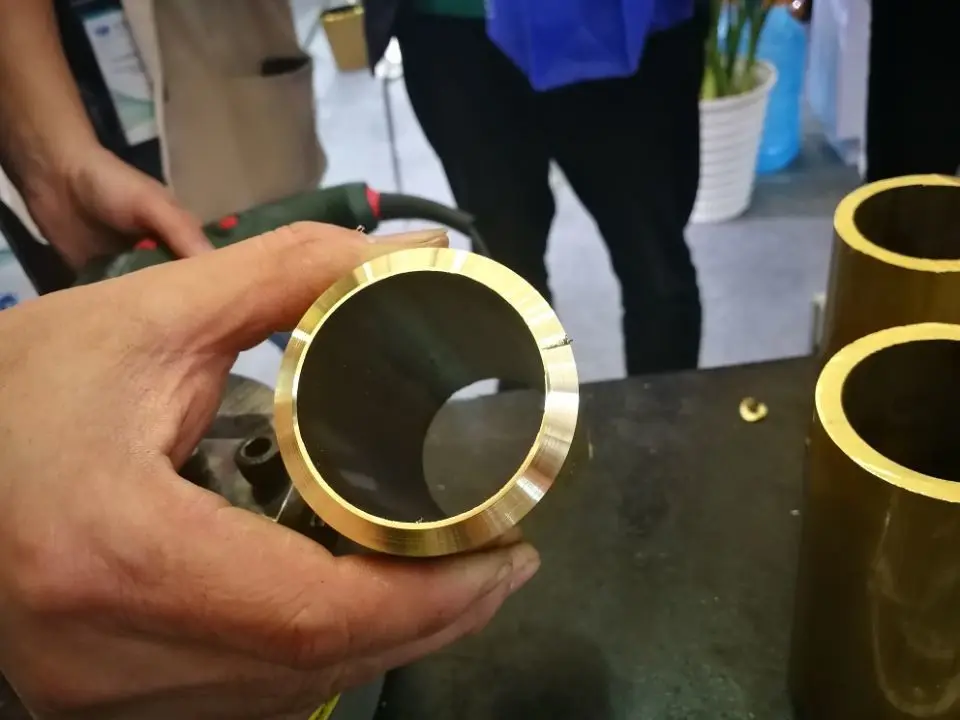

6、Cold work completely, no spark, will not affect the material;

7、High machining accuracy, good surface quality, no burr;

8、Strong adaptability, can according to the need of the machine's speed.

Tech parameters:

| The machine model | Processing range | Pipe wall thickness | The knife dish speed | The weight |

| SCB-63 | Ø14-63mm | ≤12mm | 30-120r/min | 13kg |

| SCB-114 | Ø57-114mm | ≤12mm | 30-120r/min | 16kg |

This series adopt high strength and precision structure , apply for cut and bevel work for different pipe , especially for batch,working of cutting and beveling , get the high efficiency.

Feature:

* Drive Options: Pneumatic, Hydraulic, and Electric

* Air requirement: 1500L-3000L Per minute 0.6/0.7Mpa

* Hydraulic requirement: 2-60L per minute 12.5Mpa

* Electric requirement:220-240V 1PH 50/60HZ

* Feed mode: Star wheel, automatically

* Feed rate: Fixed 0.08mm per circle

* Packaging: Plywood case.

Description of application effect

* Adjustable speed

* Self-centering , no need adjust the concentricity and perpendicularity manually.

* Easy set-up , operation and maintain

* Cutting and beveling finished at the same time , high working effective

* Cold working , no spark , won't make the material affected

Detailed Images

Cam-type self-centering cutting and beveling machine used for pipe high speed cutting and beveling suit to small size pipes.This series machine adopts METABO motor, main applied in the field of power plant pipeline installation, chemical

industry,shipbuilding, especially pipeline prefabrication and low clearance on site working, such as maintain thermal power

auxiliary equipment, boiler pipe valve.

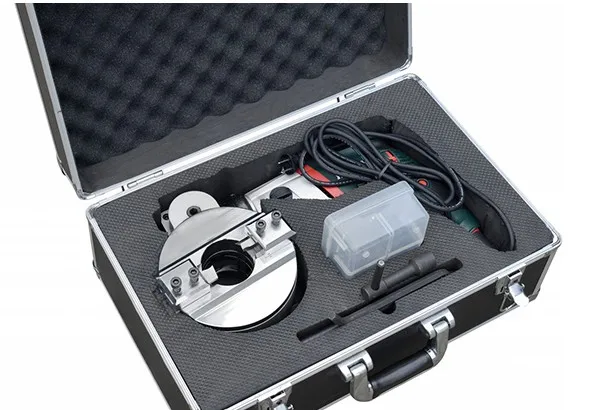

Machine standard configuration

1、Calibration clamping system,

2、Customized storage box,

3、Operating tools,

4、Product specification,

5、Qualified inspection report。