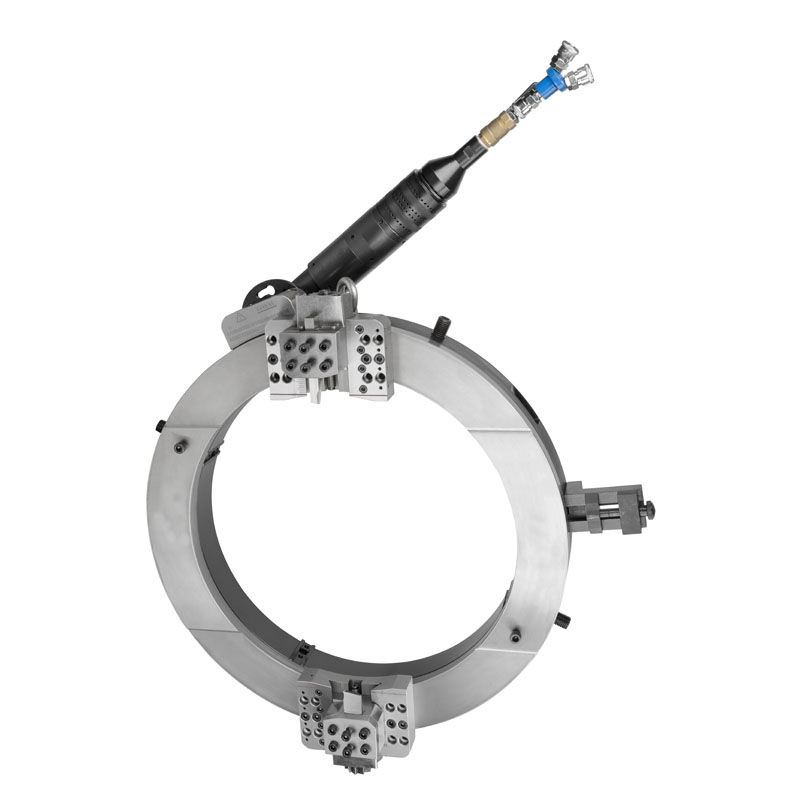

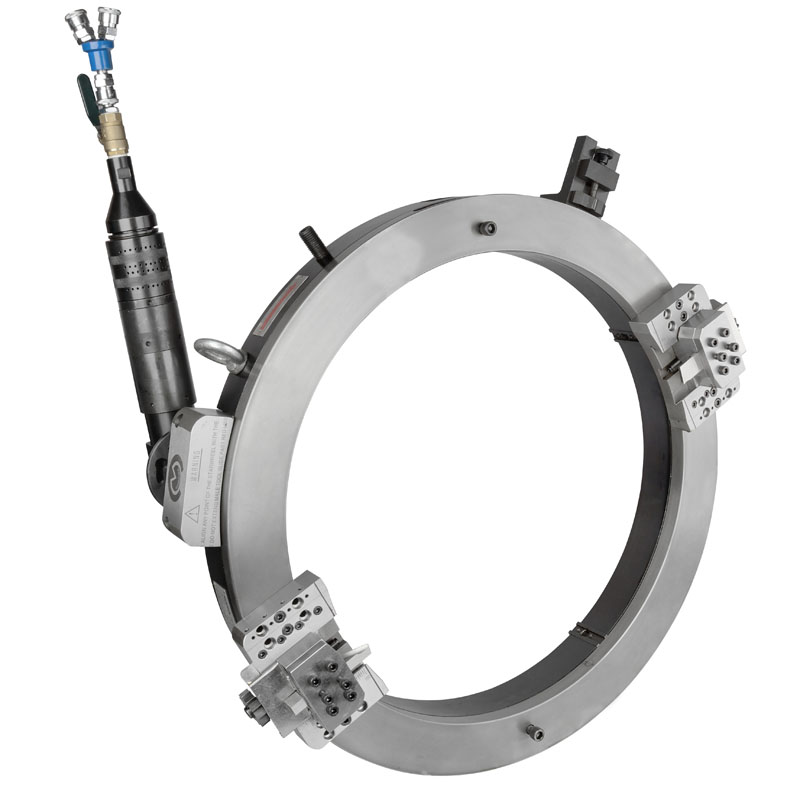

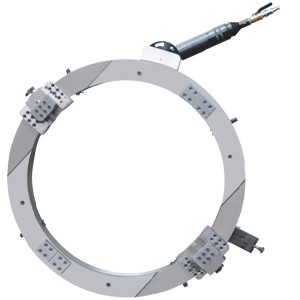

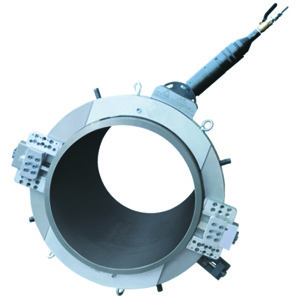

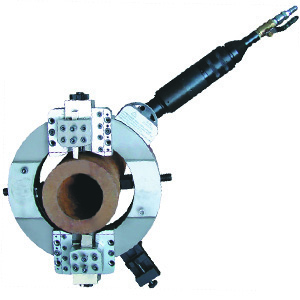

Pneumatic pipe cutting and beveling machine

Product model:OCP

Processing caliber:φ25-φ1230 1”-60”

Groove wall thickness:≤15-≤110mm

The knife dish speed:50r/min-8r/min

Product material: chrome molybdenum steel, low temperature steel, titanium alloy steel, etc.

Product standards:GB/T 156;GB 1002;GB 2099.1;GB/T 5013.4;GB/T 5023.5;GB 5226.1;GB/T 11918;GB/T 13277.1;GB 16710

summarized:

The machine adopts pneumatic motor drive, the transmission system of the special design can force the cutting effects of high intensity, there are 0.6 0.8 Mpa air can get a job, the planetary gear reducer reducer turn and rotate the ring gear transmission, make the head automatic feed, adjustable speed, once clamping, it can be finished at the same time cutting and groove processing, high precision, good performance is mainly used in flammable, explosive dangerous workplaces, the use of safe and reliable.

Machine features:

1.For carbon steel, stainless steel, alloy steel pipe processing, such as,

2.Completely cold, a bit does not affect the pipe processing,

3.Processing efficiency is high, the clamping at a time synchronization is complete cutting, groove,

4.Machining high precision, high quality, precise size, high smoothness, processing face perpendicular to the pipe axis,

5.Can be boring head assembly, tube groove or boring processing.

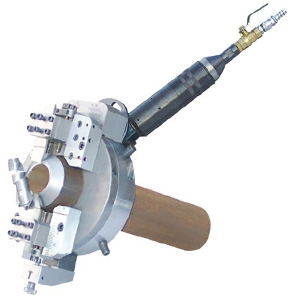

OCP Clamp type pneumatic pipe cutting groove machine main can:

This series machine is driven by motor, large cutting force, processing speed, groove are of good quality, simple operation, light weight, easy to carry, safe use, etc.This series use range is wide, not only can U, V type weld of pipe groove processing, but also the convex flange processed after butt welding.Rest on a point of view, the scale can be from 0 ° to 37 ° Angle in any processing, and there is the function of automatic feeding, simple operation, convenient.

OCP Outer clamp type pneumatic tube cutting groove machine main products performance:

1、This series is installed outside diameter type groove machine has light weight and easy to carry.

2、Easy to install, quick, lhe swelling mechanism inserted into the pipe inner can automatically locate the center.

3、The machine in addition to materials such as carbon steel, stainless steel, alloy steel pipe of the U, V type weld groove, chamfering, cutting edge processing, and the convex flange processed after butt welding.

4、Groove are of good quality, high speed, simple operation, cutting quantity adjustment, groove Angle from 0 ° to 45 ° arbitrary choice.

parameters of machine:

| Model | working range | wall thickness | Rotation Speed | ||

| OCE/OCP | mm | inch | Normal | Heavy Duty | 42r/min |

| 89 | 25-89 | 1"-3" | ≦30mm | ≦100mm | 20r/min |

| 159 | 50-159 | 2"-5" | ≦30mm | ≦100mm | 18r/min |

| 168 | 50-168 | 2"-6" | ≦30mm | ≦100mm | 15r/min |

| 230 | 80-230 | 3"-8" | ≦30mm | ≦100mm | 14r/min |

| 275 | 125-275 | 5"-10" | ≦30mm | ≦100mm | 13r/min |

| 305 | 150-305 | 6"-10" | ≦30mm | ≦100mm | 13r/min |

| 325 | 168-325 | 6"-12" | ≦30mm | ≦100mm | 12r/min |

| 377 | 219-377 | 8"-14" | ≦30mm | ≦100mm | 12r/min |

| 426 | 273-426 | 10"-16" | ≦30mm | ≦100mm | 12r/min |

| 457 | 300-457 | 12"-18" | ≦30mm | ≦100mm | 12r/min |

| 508 | 355-508 | 14"-20" | ≦30mm | ≦100mm | 12r/min |

| 560 | 400-560 | 16"-22" | ≦30mm | ≦100mm | 12r/min |

| 610 | 457-610 | 18"-24" | ≦30mm | ≦100mm | 12r/min |

| 630 | 480-630 | 20"-24" | ≦30mm | ≦100mm | 11r/min |

| 660 | 508-660 | 20"-26" | ≦30mm | ≦100mm | 11r/min |

| 715 | 560-715 | 22"-28" | ≦30mm | ≦100mm | 11r/min |

| 762 | 600-762 | 24"-30" | ≦30mm | ≦100mm | 11r/min |

| 830 | 660-813 | 26"-32" | ≦30mm | ≦100mm | 10r/min |

| 914 | 762-914 | 30"-36" | ≦30mm | ≦100mm | 10r/min |

| 1066 | 914-1066 | 36"-42" | ≦30mm | ≦100mm | 10r/min |

| 1230 | 1066-1230 | 42"-48" | ≦30mm | ≦100mm | 10r/min |

| 1430 | 1230-1430 | 48"-56" | ≦30mm | ≦100mm | 8r/min |

| 1830 | 1530-1830 | 60"-72" | ≦30mm | ≦100mm | 5r/min |

OCP Outer clamp type pneumatic tube cutting groove machine configuration

1、Calibration clamping system,

2、Customized storage box,

3、Operating tools,

4、Product specification,

5、Qualified inspection report。