Stainless Steel Pipe Cutting Equipment

Production Description

The series machine is ideal for all types of pipe cutting, beveling and end preparation.

The split frame design allows the machine to split in half at the frame and mount around

the OD of the in-line pipe or fittings for strong, stable clamping.

The equipment performs precision in-line cut or simultaneous cut/bevel, single point, counterbore

and flange facing operations, as well as weld end preparation on open ended pipe,

Operation Type:

Electric (metabo)

Pneumatic

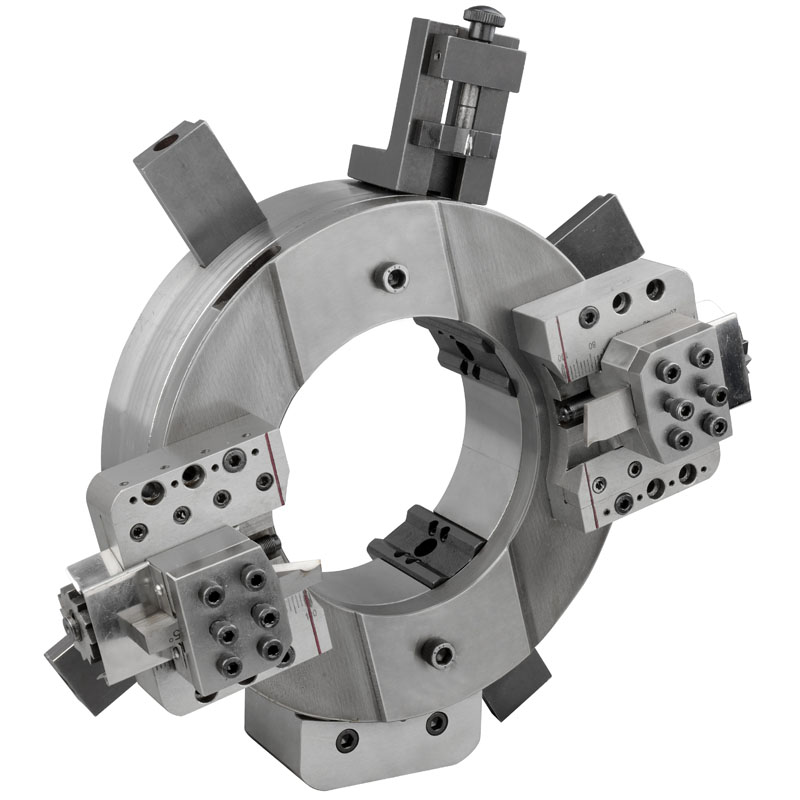

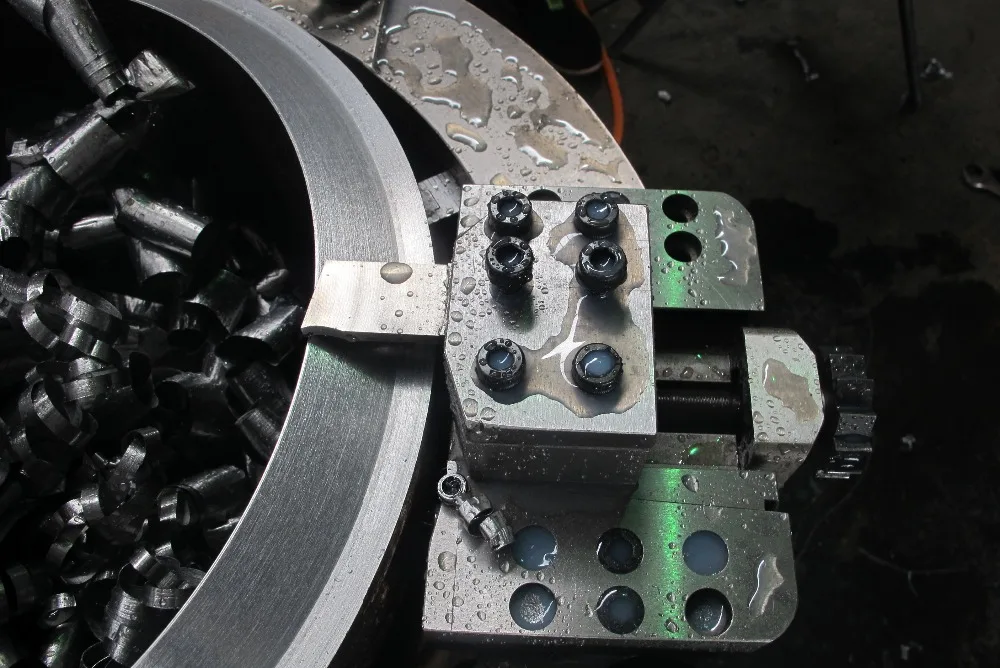

Product Show

Spcification:

Model

Working Range(ID-OD)

Wall Thickness

Rotation Speed

OCM-89

Φ25-89

3/4”-3”

≤35mm

50r/min

OCM-159

Φ50-159

2”-5”

21r/min

OCM-168

Φ50-168

2”-6”

21r/min

OCM-230

Φ80-230

3”-8’

20r/min

OCM-275

Φ125-275

5”-10”

20r/min

OCM-305

Φ150-305

6”-10”

18r/min

OCM-325

Φ168-325

6”-12”

16r/min

OCM-377

Φ219-377

8”-14”

13r/min

OCM-426

Φ273-426

10”-16”

12r/min

OCM-457

Φ300-457

12”-18”

12r/min

OCM-508

Φ355-508

14”-20”

12r/min

OCM-560

Φ400-560

16”-22”

12r/min

OCM-610

Φ457-610

18”-24”

11r/min

OCM-630

Φ480-630

20”-24”

11r/min

OCM-660

Φ508-660

20”-26”

11r/min

OCM-715

Φ560-715

22”-28”

11r/min

OCM-762

Φ600-762

24”-30”

11r/min

OCM-830

Φ660-813

26”-32”

10r/min

OCM-914

Φ762-914

30”-36”

10r/min

OCM-1066

Φ914-1066

36”-42”

9r/min

OCM-1230

Φ1066-1230

42”-48”

8r/min

OCM-1430

Φ1230-1430

50’’-56’’

8r/min

Note:Non-standard machine are available according to customers' requirement.

Machine Features:

1、Automatic potentiometric pipe center, concentricity and verticality are no manual adjustment, four claw synchronization efficient clamping, is to screw the clamping precision and efficiency of more than 10 times;

2、New type of clamping mechanism, leave out the trouble that replacement of lhe swelling block,

3、Uniform automatic feed, feed, tool longer life;

4、Easy installation fast, simple operation, convenient maintenance;

5、Cutting and groove one-time finish, high processing efficiency;

6、Completely cold, no spark, no heat affected zone;

7、High machining accuracy, good surface quality;

8、Strong adaptability, can be divided into valve installation, according to the need for speed.

Chuck type self-centering groove machine configuration

1、Calibration clamping system,

2、Customized storage box,

3、Operating tools,

4、Product specification,

5、Qualified inspection report。