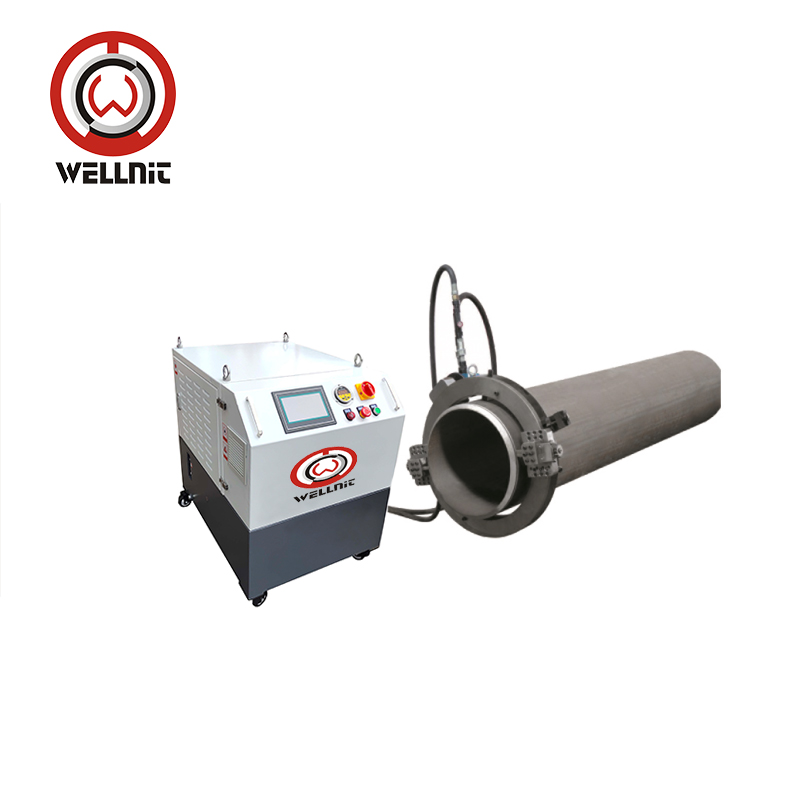

NEW TYPE POWER PACK WITH LCD screen

OLD TYPE POWER PACK

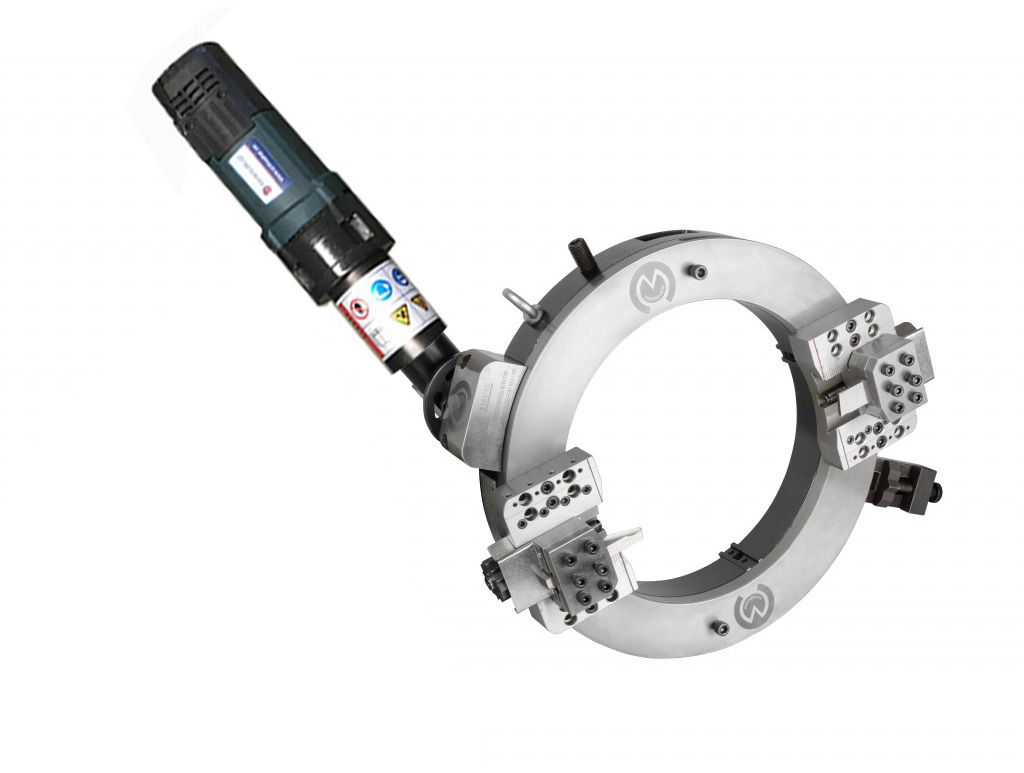

Electric Operation Type

Pneumatic Operation Type

Product model:OCH,OCP,OCE

Processing caliber:φ25-φ2030mm 1”-60”

Groove wall thickness:≤35mm-≤110mm

The knife dish speed:8-42r/min

Product material: chrome molybdenum steel, low temperature steel, titanium alloy steel, etc.

Overview:

OCH series hydraulic cutting groove machine is my company developed high-tech products, adopt unique guide bearing and eccentric adjusting structure, power output is big, the weight is relatively small, easy installation and operation, can be installed in a wireless, a clamping can complete pipe cutting and groove type of work, cold cut completely.Double feed, cutting force balance, a wild card positioning clamping, cutting vibration is small, high efficiency, the surface being machined surface of high precision, good quality, is the ideal pipe maintenance equipment at the scene.With electric, pneumatic tube cutting groove power exchange, speed adjusted.

Outer clamp type hydraulic pipe cutting groove machine use: is suitable for big pipe wall thickness, 90 or less bulk cut and groove processing.

Features in Details:

Cold Cutting and Beveling improves safety

Cutting and Beveling simultaneous

Split Frame: easy mounted on pipeline

Tools feed automatically

Fast, Precision, On-site Beveling

Minimal Axial and Radial clearance

Light weight and compact design

Easy set-up & Operation

Rugged design with vastly increased form tooling capability

Outer clamp type hydraulic pipe cutting groove machine series groove parameters

| specifications | Processing range | Cutting groove wall thickness | The knife dish speed | |

| OCH-89 | Ø25-89 | 3/4”-3” | ≤35mm | 100r/min |

| OCH-159 | Ø50-159 | 2”-5” | ≤70mm | 96r/min |

| OCH-1638 | Ø50-168 | 2”-6” | ≤70mm | 90r/min |

| OCH-230 | Ø80-230 | 3”-8” | ≤70mm | 85r/min |

| OCH-275 | Ø125-275 | 5”-10” | ≤70mm | 80r/min |

| OCH-305 | Ø150-305 | 6”-10” | ≤70mm | 73r/min |

| OCH-325 | Ø168-325 | 6”-12” | ≤70mm | 70r/min |

| OCH-377 | Ø219-377 | 8”-14” | ≤70mm | 62r/min |

| OCH-426 | Ø273-426 | 10”-16” | ≤70mm | 58r/min |

| OCH-457 | Ø300-457 | 12”-18” | ≤70mm | 55r/min |

| OCH-508 | Ø355-508 | 14”-20” | ≤70mm | 52r/min |

| OCH-560 | Ø400-560 | 16”-22” | ≤70mm | 52r/min |

| OCH-610 | Ø457-610 | 18”-24” | ≤70mm | 50r/min |

| OCH-630 | Ø480-630 | 20”-24” | ≤70mm | 50r/min |

| OCH-660 | Ø508-660 | 20”-26” | ≤70mm | 50r/min |

| OCH-710 | Ø550-710 | 22”-28” | ≤70mm | 48r/min |

| OCH-762 | Ø600-762 | 24”-30” | ≤70mm | 48r/min |

| OCH-830 | Ø680-830 | 26”-32” | ≤70mm | 45r/min |

| OCH-914 | Ø762-914 | 30”-36” | ≤70mm | 41r/min |

| OCH-1066 | Ø914-1066 | 36”-42” | ≤70mm | 32r/min |

| OCH-1230 | Ø1066-1230 | 42”-48” | ≤70mm | 30r/min |

Clamp type hydraulic pipe cutting groove machine standard configuration

1、Calibration clamping system,

2、Customized storage box,

3、Operating tools,

4、Product specification,

5、Qualified inspection report。